Professional Manufacturer of Oilfield Generators in China

HUAQUAN is a professional manufacturer of oilfield generators in China. The oilfield generators produced by HUAQUAN have the advantages of uninterrupted power supply, strong environmental adaptability, and low failure rate.

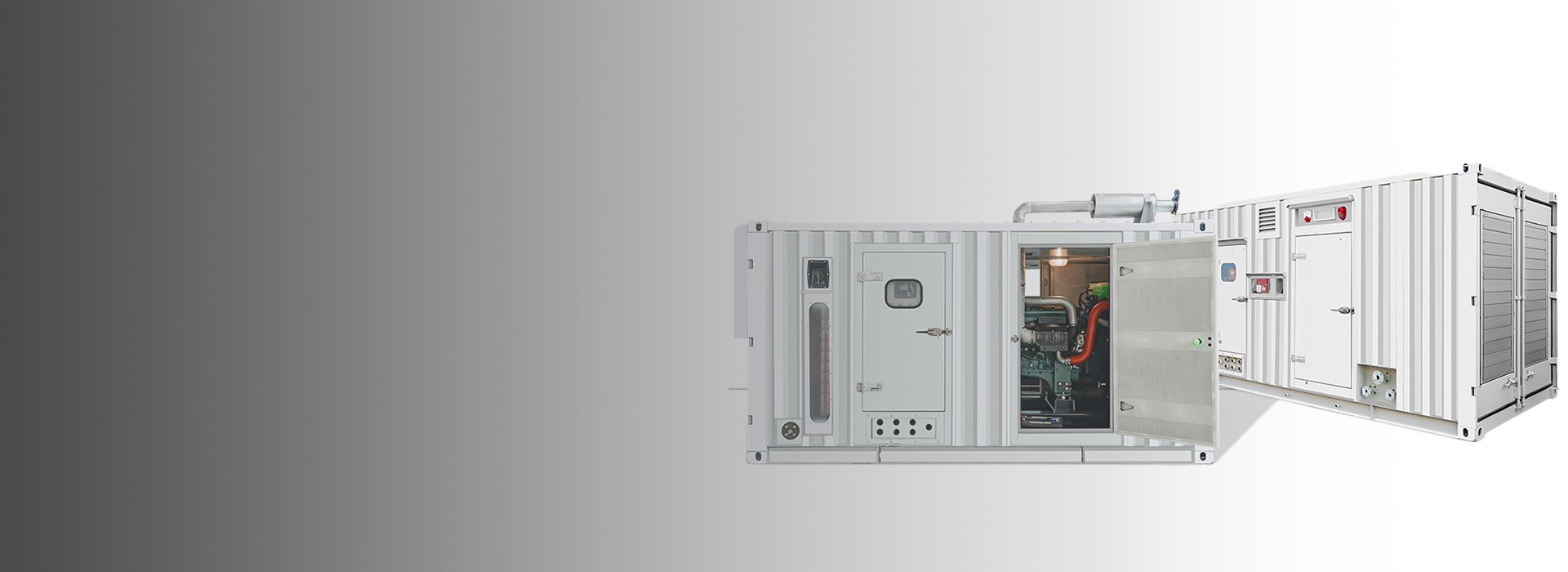

The oilfield generator is a special type of power generation equipment specifically designed and manufactured for providing power to the exploration, drilling, production, and living areas of oil and gas fields. It is not merely a simple diesel or gas generator, but rather a highly customized and fully integrated power solution capable of adapting to the extremely harsh environments of oil and gas fields.

Oilfield Generators Products

The types of generators in oilfields are diverse. When selecting a generator, it is recommended to give priority to considering the power demand and environmental compatibility.

The high-pressure common rail technology achieves a dynamic response time of ≤ 0.2 seconds, meeting the demanding conditions of heavy oil extraction and other scenarios. The explosion-proof design and special coating treatment are suitable for high-salt spray and high-corrosion environments such as offshore platforms.

The electronics speed control technology can automatically adjust the throttle according to the load, with a voltage fluctuation rate of less than 1%. The PT fuel system, in conjunction with turbocharging technology, improves fuel efficiency by 15% and the dynamic response time is less than 0.2 seconds.

Equipped with a fully copper-free brushless generator, with an insulation level up to H class, it has a low failure rate and low maintenance cost. The fully automatic system supports power supply detection, unit start/stop, and fault protection.

Equipped with an electronic speed control system, it has excellent dynamic response and the voltage fluctuation rate is ≤ 0.5%. It is coated with anti-rust and corrosion-resistant industrial paint, suitable for high-salt spray environments such as offshore oil fields.

The optimized fuel system and intake/exhaust process result in low fuel consumption rate. The ATS + multiple protection system has a short fault response time and excellent performance.

Equipped with the YC series engine, it has an overload capacity of 110%. The transient voltage adjustment range is ±20% to -15%, with a stabilization time of no more than 1 second, which meets the requirements for sudden changes in oilfield loads.

Turbocharging technology can be used in high-altitude environments. The brushless alternator, combined with an electronic speed control system, has a voltage fluctuation rate of ≤ 0.5% and a transient response time of < 0.2 seconds, meeting the power supply requirements for precision instruments in oilfields.

The modular design shortens the maintenance time on a daily basis. The explosion-proof design includes a spark extinguisher and military-grade anti-corrosion coating, which is suitable for the corrosive environment of sulfur-containing oilfields.

Functional Features of Oilfield Generators

This product can operate normally under extreme conditions such as high temperatures, low temperatures, and high altitudes.

This product equips ATS, which can restore power supply within 15 seconds after a power outage, making it suitable for sudden power outages in oilfield scenarios.

This product is equipped with an automatic pressure regulation system, eliminating the risk of electric sparks.

This product is equipped with a brushless copper core alternator and a three-stage fuel filtration system, which helps to reduce the failure rate.

The operating parameters can be monitored in real time through the mobile app, making it suitable for use in unmanned oilfield sites.

When the integrated water temperature is too high, the current is overloaded, the oil pressure is insufficient, or the rotational speed is abnormal, the system will detect these conditions and trigger automatic shutdown and alarm to prevent equipment damage.

The electronically controlled high-pressure common rail injection technology has low fuel consumption, with an effective thermal efficiency of 46%. The load adaptive adjustment reduces idle losses.

Equipped with a dual muffler structure and combined with a shock-proof base, it effectively reduces noise to meet the environmental protection requirements of the oilfield site.

Suggestions for Selecting Oilfield Generators

- Determine power requirements: Calculate the total load of all equipment and reserve 20% to 30% as a buffer.

- Fuel economy: When considering fuel economy, it is advisable to choose oilfield generators equipped with electronic fuel injection and high-pressure common rail technology; in high-altitude areas, attention should be paid to altitude power compensation.

- Environmental adaptability: The oilfield generators must undergo verification in an environment ranging from -40℃ to 50℃, and the anti-rust coating must pass a 3000-hour salt spray test. For offshore oilfields, they need to be protected to an IP23 standard or above, and in desert areas, a sand-filtering system must be installed.

- Intelligent functions: If you need remote monitoring or automatic switching, choose a model with an intelligent control system.

If you need detailed parameters or customized solutions, please provide specific usage scenarios. We will recommend the most suitable model.

Advantages of Huaguan Services

Pre-Sales Customized Consultation

Comprehensive Product Selection Guidance: Provide end-to-end product selection support, with customizable parameter adjustments to ensure precise alignment with customer needs.

In-Depth Technical Team Involvement: Our technical experts participate in detailed requirement analysis to address special scenario adaptation challenges.

Mid-Sales Implementation Assurance

Professional On-Site Installation & Commissioning: Skilled technicians deliver on-site setup and hands-on operational training.

Flexible Configuration Options: Choose from mobile trailer or container-based solutions, suitable for complex environments like oilfields and offshore platforms.

After-Sales Response Mechanism

Nationwide Service Network: Over 300 service centers across the country, with 24/7 technical support.

Regular Follow-Ups: Collect user feedback to continuously optimize service processes.

The oilfield generators rooms should be at least 50 meters away from the oil well (including the explosion-proof isolation wall). The exhaust vents need to be 3 meters above the roof and equipped with a spark catcher.

It is necessary to meet the IP54 protection standard, install a cyclone-type air filter (to be cleaned daily), use high-temperature type engine oil (SAE 15W-40 CI-4), and install a bearing sand-proof sealing device.

offshore platforms?

They need to pass a 3,000-hour salt spray test, use fully sealed bearings and anti-corrosion coatings; the control cabinet must comply with the Ex dⅡBT4 explosion-proof standard, and the cooling system uses closed-loop fresh water cooling.