A generator that runs but doesn’t make electricity is a big problem for any facility. It stops work, lowers productivity, and can make things less safe. This guide gives managers of industrial facilities and maintenance supervisors a clear and professional way to find and fix this common but serious problem.

How Generators Produce Electricity

You need to know how your generator works before you can troubleshoot it well.

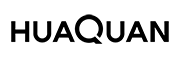

Basic generator components

Your generator has four main parts: the engine, the alternator, the voltage regulator, and the control panel. The engine makes mechanical energy, which the alternator then turns into electricity by using its rotor and stator to make a current.

Role of residual magnetism in power generation

Residual magnetism, which is a small magnetic field that stays in the alternator after it has been used, is the first step in power generation. This weak field helps make a small voltage when you start the engine, and that voltage quickly gets stronger.

How electricity is actually generated in a genset

The rotor of the alternator spins because of your engine. This causes an electrical current to flow through the stator. The Automatic Voltage Regulator then makes this output stable, so that power flows steadily.

How to Identify a Generator That Isn’t Generating Electricity

It’s important to know when your generator isn’t making electricity so you can fix the problem quickly.

Symptoms

This could mean there’s a problem if the engine of your generator is running smoothly but the equipment that is connected to it is still not getting power. Another common sign is when the control panel’s meters or digital displays show that the voltage or frequency output is zero.

How to Verify

You should check the voltage at the generator’s output terminals or the main breaker with a calibrated multimeter to make sure there is a problem. If the reading is zero or much lower than the rated voltage, it means that the generator isn’t working.

Preliminary Safety Checklist Before Troubleshooting

To keep yourself safe, make sure to follow a strict safety checklist before you start any troubleshooting. To avoid damage, unplug all loads from the generator. To keep things from starting up by accident, use the emergency stop button and lock out/tag out the main circuit breaker.

Common Causes & Solutions for No Power Output

There are a number of big problems that can make a generator run but not make power. Taking care of these common problems can often fix the issue quickly.

Tripped Breaker or Blown Fuse

The easiest reason is a blown fuse or a tripped circuit breaker. This safety feature keeps your generator from getting overloaded or shorted out. If the main output breaker on the generator set has tripped, you should check it and reset it. Check the fuses in the control panel and replace them if they are blown.

Loss of Residual Magnetism

If you don’t use your generator for a long time, it might lose the weak magnetic field it needs to start making electricity. You need to “flash the field” to fix this. This process briefly applies a low-voltage DC current from a battery to the exciter field windings to bring back the magnetism.

Faulty Automatic Voltage Regulator (AVR)

The AVR controls the voltage that comes out of your generator. If it doesn’t work, the alternator won’t get the excitation voltage it needs to make power. You usually have to replace a broken AVR. While the generator is running, you can check the voltage at the exciter field windings to see if there is any voltage.

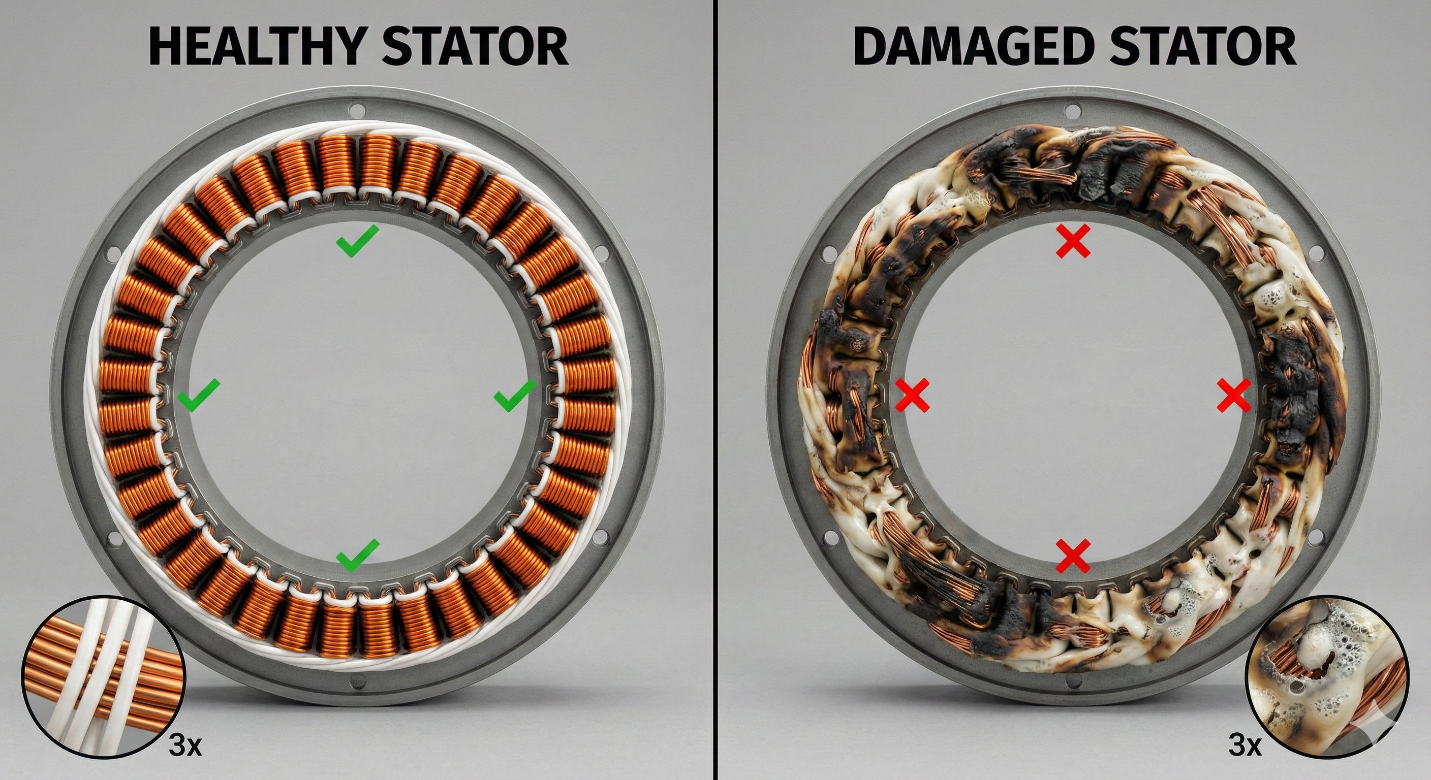

Damaged Alternator or Stator Windings

If your alternator’s stator or rotor windings get too hot or get damaged, they can short out. This internal problem stops power generation. This is a big problem that usually needs a professional to figure out what’s wrong or a technician to fix it completely. You shouldn’t try to fix internal winding breaks on your own.

Poor or Loose Electrical Connections

Over time, vibration can cause your electrical connections to become loose, which can stop the flow of electricity. If you look closely, you might see that the terminals on the alternator, AVR, or circuit breaker are corroded or loose. If this is the problem, tightening these connections and cleaning your terminals can often fix the power output.

Control Panel and Sensor Errors

Modern generators use advanced control panels and sensors. If a sensor doesn’t work right, it could tell your control system that there is a problem, which would stop power output. You should look at the control panel to see if there are any active error codes or alarms, and then use the manual from the manufacturer to find out what the problem is.

Faulty Capacitor or Diode Problems

Capacitors and diodes are important parts of your alternator that help keep the voltage stable. If a capacitor fails, it can stop the voltage buildup process. If a diode fails, it can stop the current in the exciter field. You need to test each of these parts on their own and replace them if they are broken or not working.

Overload and Wiring Issues

An immediate overload when you start up can trip your safety systems and stop output. You need to make sure that no load is connected when you start up. Also, if the wiring between your generator and the transfer switch is broken or wrong, it can stop power from getting to you, even if the generator is making the electricity you need.

Step-by-Step Diagnostic Guide

Use this step-by-step method to quickly figure out why your generator isn’t making power.

Visual Inspection

Start by giving your generator a thorough look over. Make sure there are no blown fuses or tripped breakers, and check for cables that are loose, broken, or not connected. Check your control panel for lights or alarms that might be on. A lot of the time, this simple check can help you find the problem quickly.

Output Voltage Test

Use a multimeter set to AC volts to check the output terminals while your generator is running without any load. If the reading is close to zero, it means the generator isn’t making any power. This step makes sure there is a problem before moving on to more tests.

AVR and Regulator Checks

Check the DC voltage from your AVR (Automatic Voltage Regulator) to the exciter windings if you don’t see any output voltage. The AVR may be broken if there is no voltage. If there is voltage, the alternator could be the problem.

Residual Magnetism Flash

You can fix a generator that has lost its residual magnetism by doing a field flash. For a few seconds, turn off your generator and connect a 12V DC source to the exciter field leads. This often helps restore the magnetism needed to make the right voltage.

Control Panel Error Codes

Look for error or diagnostic trouble codes (DTCs) on generators with digital control panels. These codes point to specific problems and can help you fix them. To understand the fault and read the codes correctly, use the manual that came with your generator.

When to Stop and Call a Professional

Stop testing if basic troubleshooting doesn’t fix the problem or if you think the internal alternator is broken (for example, the rotor or stator). At this point, you should call a certified generator technician to get a more in-depth diagnosis and repair.

Preventive Maintenance Tips to Avoid Future Problems

The best way to make sure your generator works when you need it to and doesn’t break down unexpectedly is to do regular maintenance on it.

Regular Testing and Load Running

Every month, put a heavy load on your generator for a set amount of time. The best load is about 50% of its rated capacity. This process, known as load testing, stops diesel engines from getting wet. It also makes sure that the electrical parts of your generator work well when they’re under stress, so it’s always ready for real-world needs.

Scheduling Professional Servicing

Make a service agreement with a qualified generator technician to check and fix your generator on a regular basis. Professionals can find problems like worn bearings, weak insulation, or problems with calibration before they happen. This proactive method keeps your generator running smoothly and reliably for a long time and helps you avoid unexpected breakdowns.

Cleaning Generator Contacts, Air Filters and Terminals

To keep your generator’s electrical contacts and terminals from rusting and to make sure they are strong, check and clean them often. To keep the right amount of air flowing, which helps with combustion and cooling, clean or replace the air filters. Cleaning your generator lowers the chance of it overheating, which protects delicate parts and makes it work better over time.

Running Generators Monthly to Preserve Residual Magnetism

Even if you don’t have a load, you should start and run your generator for 15 to 20 minutes every month. This helps keep the rotor’s magnetism, which makes sure the generator is ready to make power. It also keeps the battery charged, lubricates engine parts, and stops problems that can happen when the generator isn’t used for a long time. This helps the generator stay reliable.

Conclusion

If your generator runs but doesn’t make power, start by checking simple things like breakers. sThen, do more complicated tests like AVR testing. Put safety first and know when to call in the pros. Our trained technicians are here to help. Call us today to set up a service or talk about what you need from your generator.

FAQs

Why is my generator running but not producing power?

This happens a lot because your circuit breaker tripped, you lost residual magnetism, or your automatic voltage regulator isn’t working right anymore.

Can poor electrical connections stop power output even if the generator is running?

Loose or rusty connections can break the electrical path, which stops your generator from sending power to your home or tools.

How do I test generator output voltage?

While your generator is running and nothing is plugged into it, set your multimeter to AC volts and check the output terminals.

Can loss of magnetism be prevented?

You can stop this from happening by starting your generator and letting it run for about twenty minutes every month to keep the magnetic field strong.

Can a damaged stator winding cause no electricity output?

Yes, your generator won’t be able to make the electricity you need if the stator windings are broken or shorted.

Is AVR replacement expensive?

Replacing the regulator is usually a lot cheaper than buying a whole new generator or alternator, but the price depends on your model.