Professional Gas Generator Manufacturer in China

Through cooperation with brands such as WC, YC, KMS, and SC, HUAQUAN has continuously optimized and upgraded its products, ensuring reliable quality. The intelligent manufacturing workshop has introduced fully automatic spraying lines, industrial welding robots, AGV transportation platforms, and CNC machines etc. It has strong technical reserves and high production efficiency.

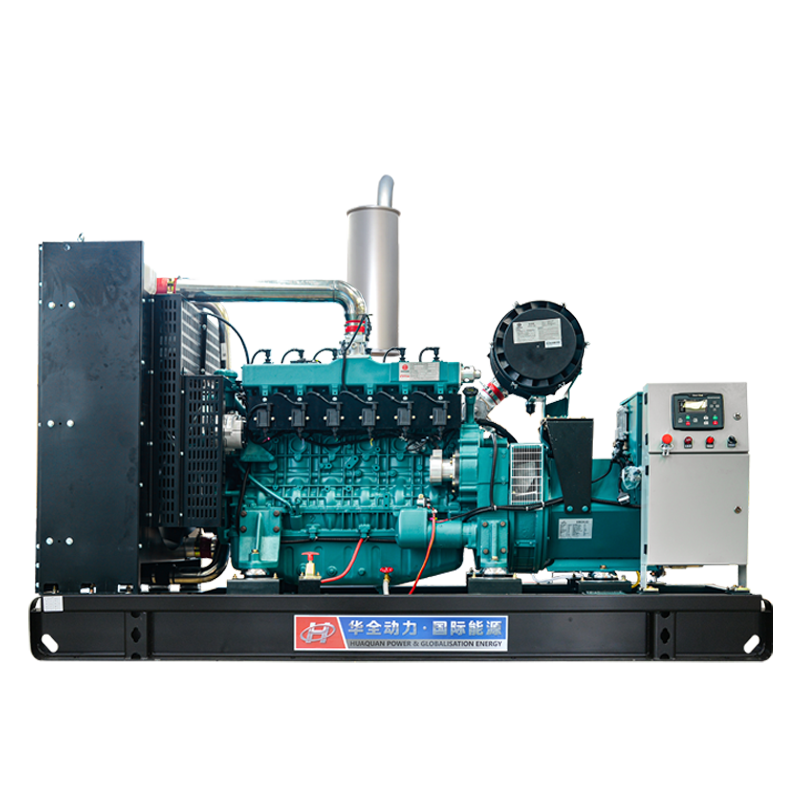

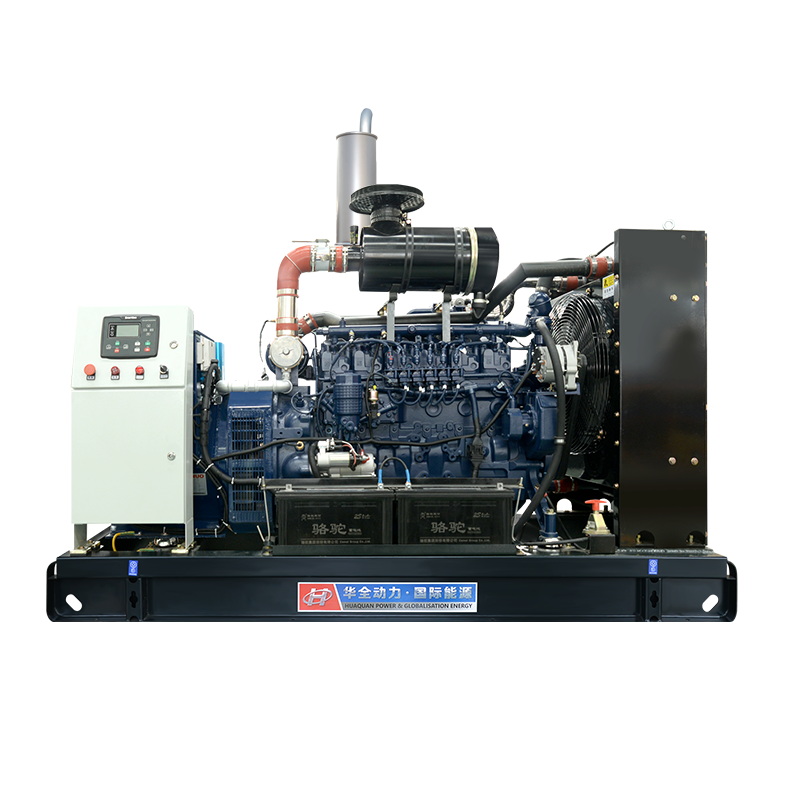

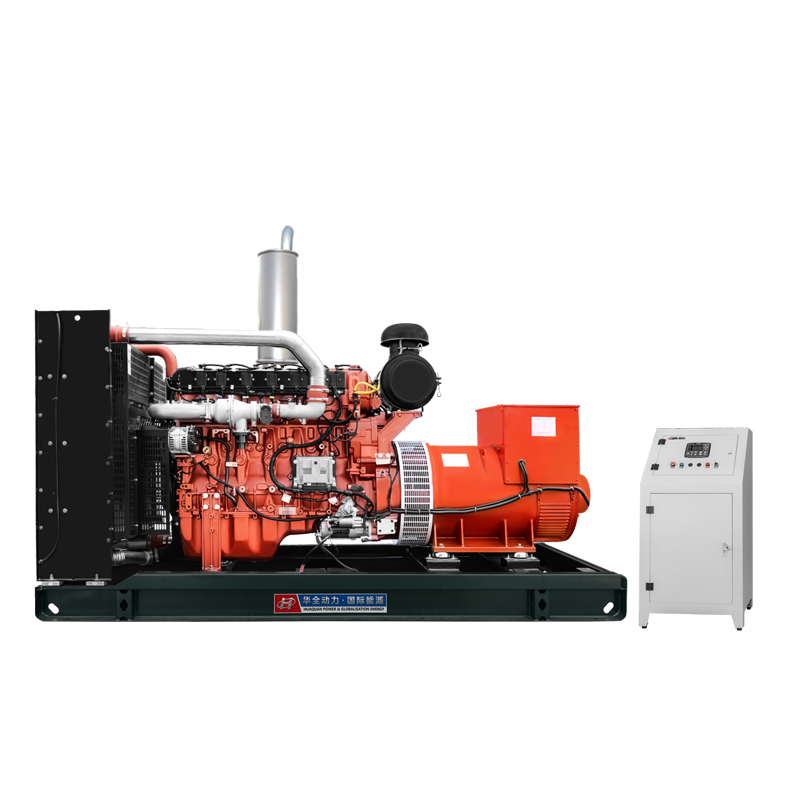

HUAQUAN gas generator adopts a full-copper brushless alternator with an extended silicon steel sheet core. It has strong power, sufficient output power, excellent cost performance, long lifespan, and low maintenance cost.

HUAQUAN gas generator employs the latest ECU technology to optimize gas combustion efficiency and reduce the failure rate.

The HUAQUAN gas generator achieves its stability in operation through systematic optimization design, integration of intelligent intake regulation, efficient waste heat recovery, and deep desulfurization and dehydration technologies. After undergoing rigorous testing and verification procedures, it can ensure the reliability and environmental friendliness of the power generation solution provided to you.

HUAQUAN Gas Generator Products

The HUAQUAN gas generators are compatible with various fuels and are equipped with intelligent control technology. They have significant advantages in fields such as agriculture, livestock breeding, and power supply in remote areas.

HUAQUAN’s associated petroleum gas generator set efficiently convert the “waste gas” of oilfield associated gas into valuable power resources. This is not only a technology but also a comprehensive solution that integrates “economy, environmental protection and reliability”. It helps enterprises turn waste into profit and achieve the dual goals of resource recycling and energy conservation and emission reduction.

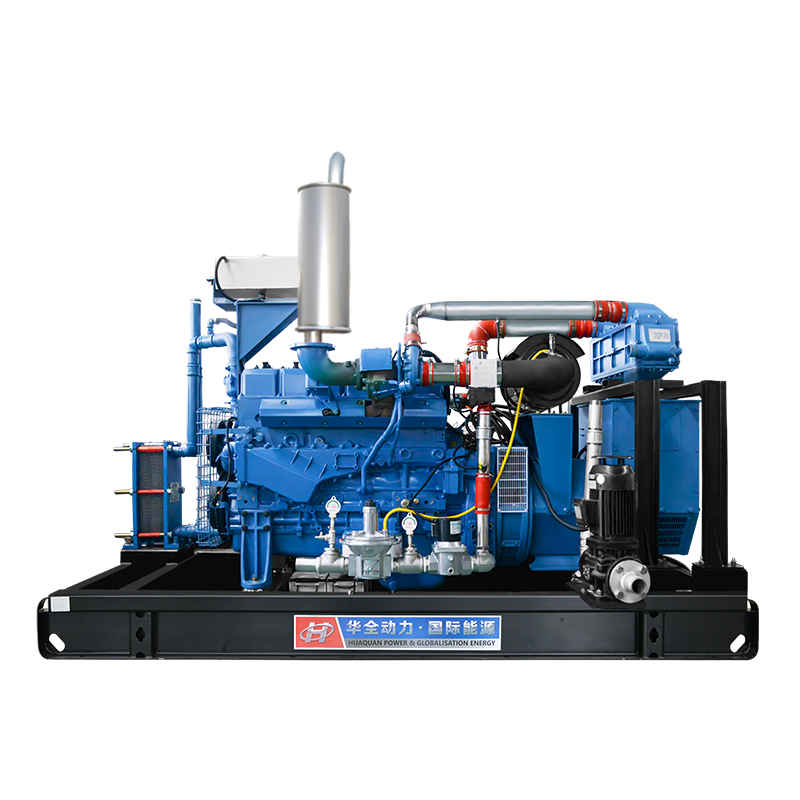

HUAQUAN biogas generator is equipped with engines from brands such as YC and SC. The key sensors are imported, and it is also equipped with HUAQUAN Cloud Intelligent Control System. It can automatically adjust the air-fuel ratio to address the instability issue of biogas production.

This biogas generator is equipped with an electronic speed regulation system. The ECU precisely regulates the gas supply and engine speed. The speed sensor continuously monitors the engine status to ensure that the biogas generator operates in good condition under different working conditions.

Garbage incineration generator is an environmental protection device that uses high-temperature incineration to treat household waste and generate electricity through thermal energy. Its core principle is to convert the thermal energy generated by garbage incineration into electrical energy, while achieving waste reduction and resource utilization.

Functional Features of Gas Generator

Multi-level explosion-proof design, safety upgrade.

Lean combustion consumes less energy and saves operating costs.

Realize the multi-level utilization of energy and achieve high overall efficiency.

Reducing the electricity consumption during peak hours and increasing the electricity consumption during off-peak hours. Together, these measures help achieve grid balance.

Suitable for gases such as natural gas and biogas, with low fuel costs

From cold start to full load, it takes only 30 seconds. The ATS switching response is less than 10 seconds.

Equipped with a cloud monitoring platform, the accuracy rate of fault prediction is very high.

Reduce carbon emission by 60% and meet relevant environmental protection requirements.

The Advantages of HUAQUAN’s Service

Whether it is before sale, during sale, or after sale, HUAQUAN is committed to optimizing processes and controlling details, ensuring that customers can buy with confidence and use with ease. HUAQUAN’s services are professional, dedicated, courageous in taking responsibility, and of excellent quality.

Pre-sale: Sales staff provide guidance to help you select the appropriate products.

During the sale, On-site services are available for installation and to guide the debugging and usage of the equipment.

After-sales: The service network is well-established, with prompt response. There are over 300 user service stations across the country. Group operation ensures worry-free after-sales services.

Advantages of HUAQUAN Production and Manufacturing

As a professional manufacturer of gas generators in China, HUAQUAN has an intelligent production base. The large-scale and standardized production is conducive to cost control, and the modular customization ensures the quality consistency (QC) and stability of product quality.

HUAQUAN has established long-term and stable cooperative relationships with suppliers of engines, alternators, and control systems, forming a complete industrial chain, ensuring stable supply and maintaining a price advantage.

HUAQUAN’s production line is equipped with professional testing equipment that can simulate real working conditions and conduct full-load tests to ensure strict quality control. Only after each gas generator has been verified to be reliable in performance can it be released from the factory.

Advantages of HUAQUAN Sales and Services

HUAQUAN has established extensive sales and service outlets both nationally and globally. When there is any abnormality with the gas generator, it can respond promptly and solve the problem in a timely manner, thereby minimizing the downtime losses for users.

HUAQUAN relies on our extensive spare parts warehouse and robust supply chain to ensure the precise and efficient supply of gas generator components, eliminating any concerns for our customers.

HUAQUAN not only sells products but also offers a one-stop solution. From site survey and design to installation and commissioning, as well as operation and maintenance, it covers the entire project life cycle.

The gas generator converts chemical energy into electrical energy by burning natural gas. The core process is as follows: Gas (such as methane) is mixed with compressed air in the combustion chamber or cylinder and ignited, generating high-temperature and high-pressure gas that drives the turbine blades to rotate (in a gas turbine) or the pistons to reciprocate (in an internal combustion engine). The mechanical energy is transmitted through the coupling to drive the generator rotor to cut through the magnetic field lines and generate electricity. Thus, the conversion of chemical energy → heat energy → mechanical energy → electrical energy is completed.

The key requirements for the fuel of a gas generator include: The fuel must be a dry and dehydrated combustion gas (such as natural gas, biogas, etc.). The methane content of natural gas should be ≥ 70% (biogas ≥ 40%), hydrogen sulfide should be ≤ 20mg/Nm³, moisture should be ≤ 40 g/Nm³, and the particle size of impurities should be < 5μm. The intake pressure needs to be stable at 80-200kPa (for biogas, 3-100kPa), and the pressure fluctuation rate should be ≤ 1kPa/min. If there are corrosive components such as sulfur and ammonia, they need to be pre-treated to safety limits to avoid damaging the internal parts of the generator.

Gas quality: Biogas needs to be treated for sulfur removal to prevent corrosion of the engine.

Fuel system inspection: Ensure stable gas pressure, no leakage in the pipeline, clean filters, and no blockage by impurities.

Engine oil and coolant management: Regularly check the oil level and quality, and replace the oil at the scheduled time; maintain sufficient coolant to prevent overheating.

Spark plug/ignition system inspection: Remove carbon deposits, adjust the gap, and ensure proper ignition (applicable to gas internal combustion engines).

Long-term storage: Empty the gas system, prevent moisture and rust.

Note: Maintenance details may vary for different models. Please refer to HUAQUAN’s user manual for implementation.

The purpose of a gas generator is to produce gas by burning fuel or a chemical reaction. The produced gas is both hot and under pressure; hence, it can be used to power machines or engines. The continuous aim of these generators is to develop gas that can power different systems. Examples of these uses include:

● Engines for operating machines & vehicles

● Turbines for producing electricity in power stations

● Provide the force to launch rockets

● Industrial systems for powering different processes

Now you know what a gas generator is, but do you know the internal process? How do the gas generators actually work? Here, we will explain the process in the easiest way. For many advanced systems, even though a gas generator is used, the basic working principle is quite easy. A few steps involved in how gas generators work are listed below.

Step 1: Initiation of Fuel

The first step in the working of gas generators is the burning of fuel or chemical reaction. Natural gas, liquid fuel, or even a solid chemical material that serves as fuel is mixed inside the gas generator. This process is done to ensure fuel can safely be burnt inside the gas generator. However, in some gas generators, a chemical reaction is used instead of burning fuel.

This process generates a lot of heat; therefore, to safely handle this, the gas generator is designed accordingly. The only goal of this process is to create the amount of heat so it will start producing gas.

Step 2: Gas Is Produced

After the burning of fuel or chemical reaction, the formation of gas starts inside the gas generator. With an increase in temperature, the gas starts to build more pressure inside the gas generator. This is a crucial step in the functioning of gas generators, as gas generation requires both heat and pressure.

The gas generator is designed to allow for easy control regarding how much gas can be produced or how fast it can accumulate. Additionally, the materials required are of high quality in order make sure the generator handles temperatures and pressures safely.

Step 3: Gas Is Controlled and Directed

Another key step involved in how gas generators work is controlling the gas flow properly. You should not release the hot and high-pressured gas all at once. Instead of releasing all at once, the gas is passed through pipes or openings while maintaining control. This helps in avoiding any type of damage in between and ensures smooth operation.

Step 4: Gas Is Used to Do Work

This is the last step of the gas generator working process. This is where the gas is used for performing different types of tasks. For example, the gas is used to operate engines, move turbines, and move the industrial machinery parts. However, after this, the gas can either be reused or released depending on the system.

Choosing the right gas generator is important because choosing the wrong one could cost you more and lead to poor performance. Understand the below factors before choosing the right gas generator:

Power Requirements

The very first thing you need to understand is the power requirements. If you don’t need much energy or power, you can go with a small generator. On the other hand, for big equipment, you will need bigger generators.

Application Type

Next, think about where and how you will be using the generator. There are gas generators manufactured for use in industries and others suited for backup power and portability.

Efficiency and Reliability

When selecting, make sure the generator you choose is also efficient. Choosing the efficient one makes sure they will use the fuel carefully while reducing the overall operating cost.

Conclusion

A gas generator is an important device for producing gas, which is then used to power multiple machines and engines. These systems help industries perform their operations smoothly by providing a reliable and efficient power source. However, choosing the right type of gas generator is important to efficiently fulfill your requirements.

Understanding how gas generators work is vital because they are used in many applications across multiple industries and fields. Whether it’s about generating electricity or providing support to advanced machines, they are used in different types of industries. One more key benefit of using gas generators is they are suitable for both small and large applications.

Types of Gas Generators

Not all gas generators are the same. There are different types of gas generators designed for different purposes. Knowing the key details about different types helps you choose the right generator that will fulfill your needs:

Chemical Gas Generators

This type of gas generator creates gas through a chemical reaction instead of fuel burning. When the chemicals react, the gas is released quickly while maintaining control. This is mostly used when we need fast and reliable gas production, such as in rockets and emergency systems.

Combustion-Based Gas Generators

This type of gas generator produces gas by burning fuel. This is one of the most common types of gas generators used by most of the manufacturing companies. However, they are mostly used in engines, turbines, and power plants.

Industrial vs Portable Gas Generators

Industrial gas generators are large and powerful. They are used in places such as factories, power plants, and heavy industries. Moreover, they are especially useful for long-term operations.

Portable gas generators are smaller and less powerful as compared to industrial gas generators. They are mostly used for temporary power needs and as backup systems.