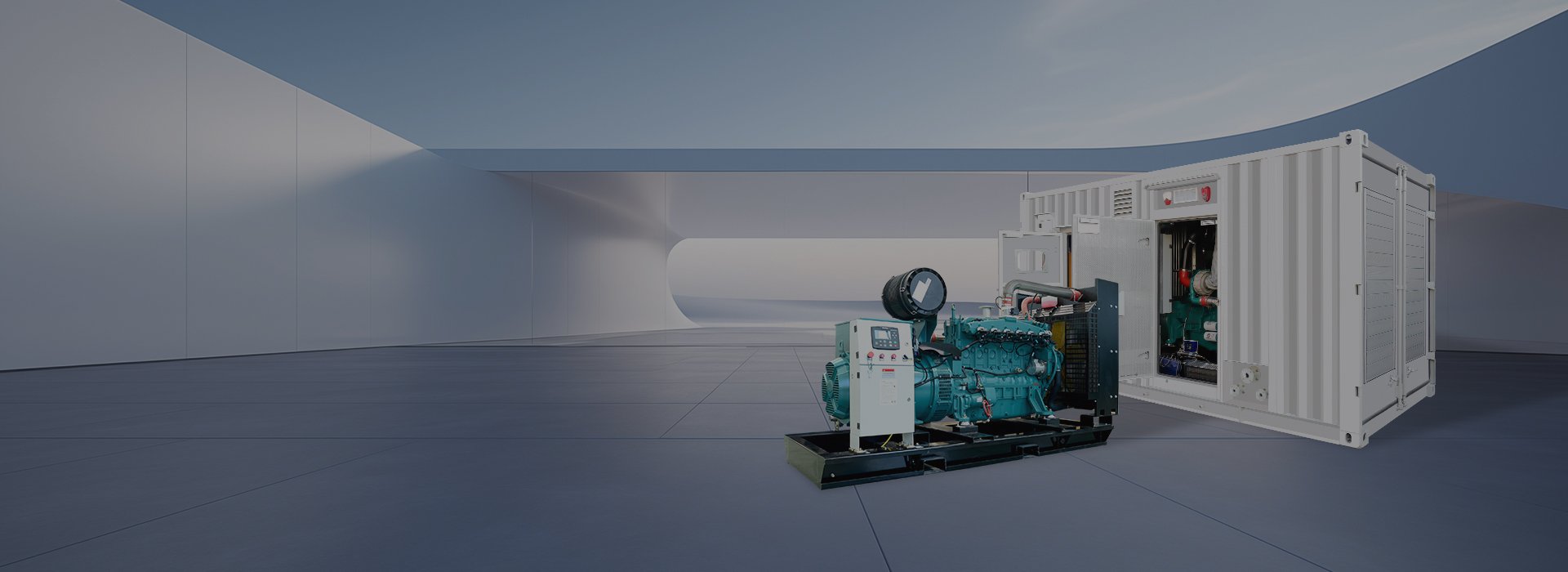

China’s Professional Manufacturer for Farm Generators

HUAQUAN is a professional farm generator manufacturer in China, integrating R&D, manufacturing, sales, and operation & maintenance. We provide customized power solutions for your livestock farm, covering gas power and diesel power generation.

The HUAQUAN farm generators have a power range of 50 to 2000 kW, supporting multi-machine grid connection operation. The power can be adjusted as needed to reduce fuel consumption. The full-copper brushless motors of HUAQUAN’s farm generators ensure stable output current and are suitable for precision temperature control, ventilation, aeration machines, circulating water pumps, etc. The farm generators of HUAQUAN are equipped with a fully automatic control system. In case of a power outage, they can automatically start and supply power to ensure a continuous power supply.

Farm Generators Series

The engine adopts brands such as YC, WC, KMS, WF, and SC, and combines with independent optimization technology to enhance the overall performance of the generator in the breeding farm.

Equipped with a WC engine, it holds various domestic product certification qualifications, possesses excellent environmental adaptability and loading capacity, and features low fuel consumption through high-pressure common rail technology.

Using a V-type 12-cylinders engine combined with a pure copper brushless alternator, the single machine has a wide power coverage range, quick loading response and stable operation.

This series of products optimizes the combustion technology, significantly enhancing the fuel utilization rate and ensuring the stability of the equipment in harsh environments. Moreover, it places great emphasis on intelligent operation and maintenance, and can provide customized solutions for users.

This series of products adopts advanced combustion technology and turbocharging system, significantly improving fuel efficiency and reducing operation costs. This high-power diesel engine can support continuous operation for a long time and meet the requirements of high-intensity usage.

This series of products is equipped with a high-pressure common rail fuel system, which leads to a high fuel injection pressure and an improved combustion efficiency compared to traditional models. The electronic control common rail technology reduces the overall fuel consumption and ensures stable operation.

This biogas farm generator uses biogas as the main fuel, and it is a new type of green power equipment. It adopts an intelligent air-fuel ratio control system, which ensures high combustion efficiency and low pollution. It is applicable in fields such as livestock farms, landfill sites, and industrial wastewater treatment.

After combustion natural gas farm generators mainly produce CO₂ and water, with low pollutant emissions, which complies with relevant environmental protection requirements.

The gas generator, as a clean energy equipment, adopts advanced combustion technology and has a high energy conversion efficiency. It can be remotely set to start or stop at the voltage threshold through Bluetooth connection on a mobile phone. The gas farm generators are equipped with multiple protective mechanisms such as high-voltage automatic shutdown and short-circuit protection to avoid damaging the battery.

Function Features of the Farm Generators

Equipped with the ATS automatic transfer switching system, it can automatically repower the electricity within 3 to 10 seconds after the main power grid is cut off, ensuring the continuous operation of critical equipment.

The outer shell and core components of the generator in the farm are coated with anti-corrosion paint to resist the high humidity and ammonia corrosion in the farm environment.

Three-level noise reduction structure (for intake/exhaust/mechanical noise reduction), with noise level no more than 75 dB at 7 meters away, to prevent disturbing livestock.

It supports real-time monitoring of the operation status on the mobile device, automatically trigger alarms for fault and generate judgment reports.

The key components (such as the engine) have a long design lifespan.

Optimizing the combustion system can reduce energy consumption and meet environmental emission standards.

Multiple farm generators can be connected in parallel for use, allowing for flexible capacity expansion and enhancing power supply redundancy.

The modular design enables easy replacement of components such as filters and batteries, reducing downtime.

Key Points for Selecting Farm Generators

When selecting farm generators, factors such as power matching, system functionality, and emergency plans need to be taken into consideration comprehensively:

Power calculation and scalability: Accurately calculate the total power demand of the farm (including pumps, ventilation, temperature control, and other equipment), and add a 20%-30% safety margin if the power demand is large. A parallel operation scheme can be adopted to save costs.

Intelligent control system:

It is preferable to select the farm generators equipped with remote monitoring and automatic shutdown functions. It can monitor faults in real time and complete the power outage switching within a short period of time.

Emergency plan and equipment redundancy:

It is recommended to install two sets of equipment, one in use and one as a backup. The main and backup systems can be switched to minimize power outage losses.

Customization Process of Farm Generators

The HUAQUAN engineers will provide an electricity solution for your farm through the following process:

Demand alignment: Understand the electricity environment and the electricity demand of your farm, and analyze the load characteristics.

Solution configuration: Comprehensive consideration of power matching, system functions, maintenance costs, and emergency solution configuration.

Production testing: Customized equipment, selection of high-quality components, strict quality control process, personalized function configuration.

Delivery and operation: A Professional team conducts multi-condition tests and provides a supporting intelligent monitoring system and long-term spare parts supply system.

The battery needs to maintain the continuity of the series circuit. Before starting that the oil level is within the upper and lower limits of the gauge and that the antifreeze level if (below the sealing cover by 5 cm). In coastal areas, the integrity of the anti-corrosion coating of metal components needs to be checked monthly. The oil filter should be replaced every 250 hours of operation; the cooling system should be cleaned every 500 hours.

Basic formular: Total power = 1.2×(pump power + aeration machine power + total power of other equipment), and 30% expansion space should be reserved.

It depends on what type of generator is used in the farm. The price of farm generators is mainly influenced by power, brand, configuration (such as silent/anti-corrosion design), and market supply and demand. The greater the power and the better the configuration, the higher the price. In addition, technical complexity such as automatic control, fluctuations in raw material costs, and after-sales service policies can also significantly affect the price. When selecting a farm generator, you should consider factors such as power, brand, and configuration comprehensively and select the appropriate one.