You are a power engineer, maintenance technician, or business owner; understanding remote settings for diesel generators is essential. Remote operation settings allow complete control over the power supply from any industrial generator. From tracking fuel storage and leaks to assessing load capacity and identifying issues, remote controls help you generate sustainable energy safely.

What Is Remote Monitoring For Diesel Generators?

Remote monitoring lets you track the diesel generator’s key performance metrics and analyze them in real time. In an emergency, you receive quick alerts and catch minor issues before they escalate into major, uncontrollable problems. With remote operating systems for your diesel generators, you reduce downtime and lower costs.

There is no limit to the number of machine data streams you can track. You need one reliable remote monitoring system that covers all your machinery and equipment on a single screen. Nowadays, many industrial generators come with advanced cloud-based technology that continuously monitors data.

Why You Need Remote Monitoring for Diesel Generators?

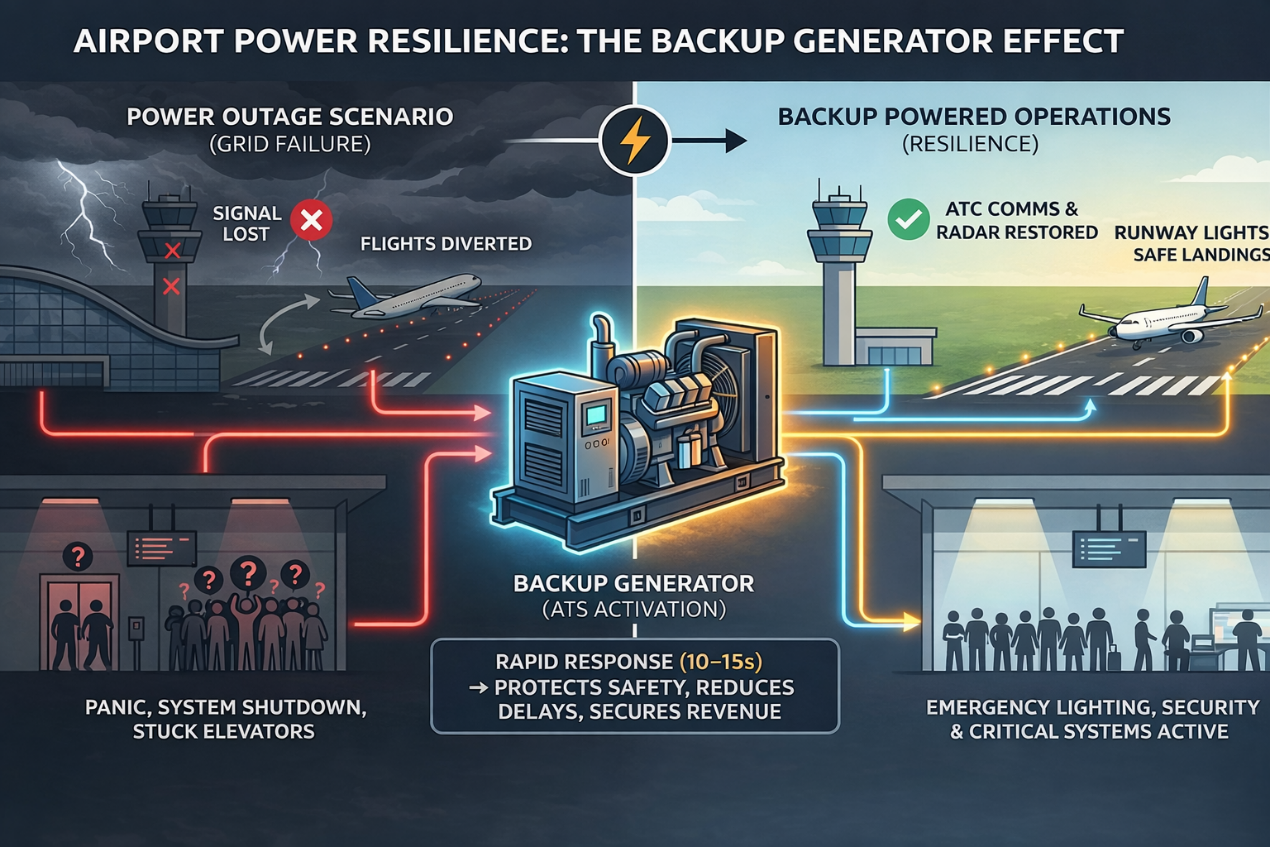

Diesel generators are the primary source of power during grid failures and as backup power. You gain complete control by integrating a remote tracking system, ensuring safety and reducing risk.

Central Monitoring Parameters You Can Track with Remote Settings

Remote systems for industrial generators help decrease labor costs, reduce physical inspections, and save time. Find problems early and fix them before you face trouble.

If you are a power engineer or any engine technician, a remote screen helps you track real-time performance. You can analyze every detail and fix errors promptly to keep the workflow smooth.

Main Monitoring Parameters You Can Track with Remote Settings

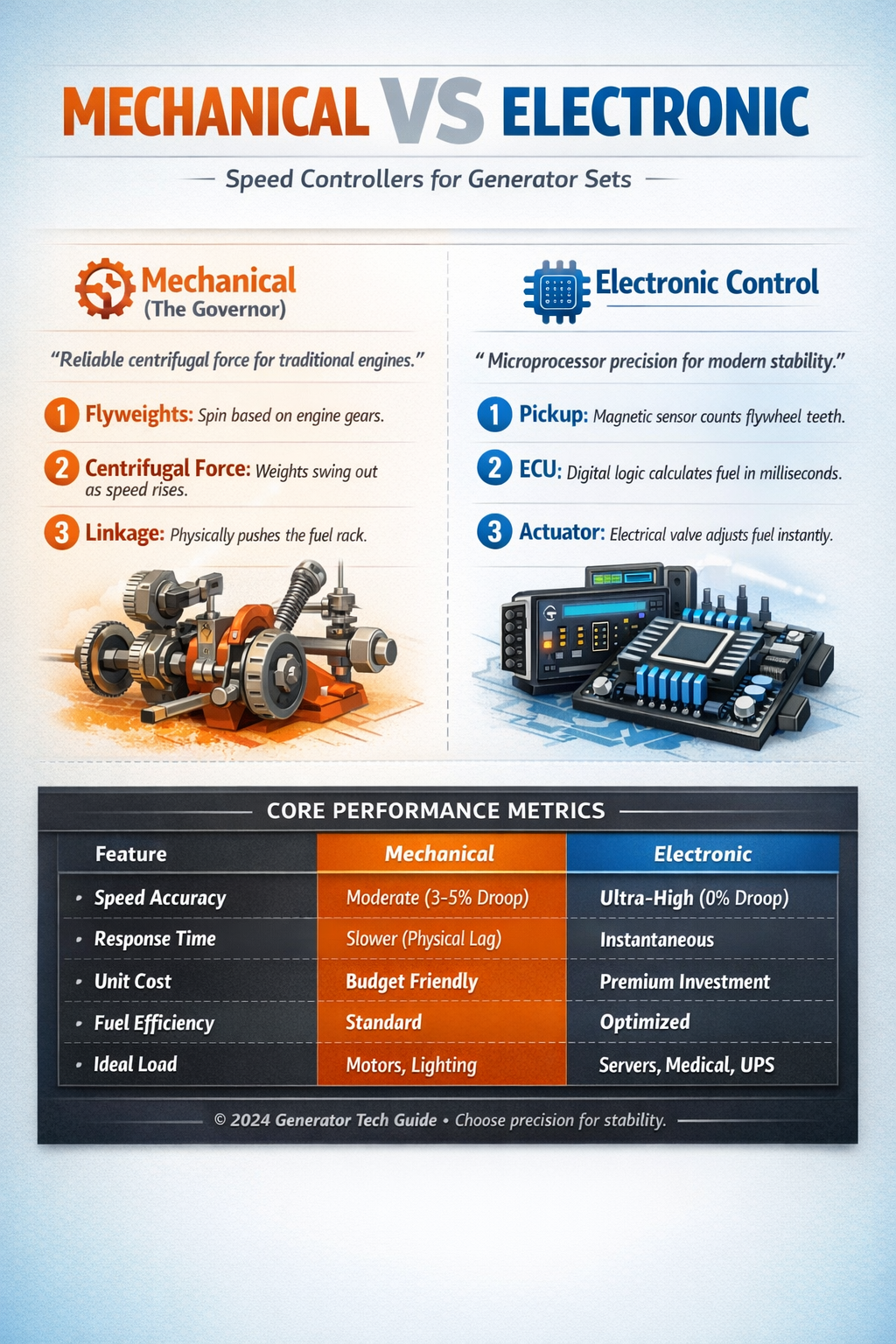

Here is a short list of what you can track with remote monitoring and operation settings for diesel generators:

Fuel level

Fuel consumption

Engine temperature

Oil pressure

Battery voltage

Power output

Voltage and frequency

Engine runtime

Load percentage

Fault and alarm status

Tracking all these critical metrics within your remote monitoring and operations system helps ensure safe power generation. You can work with a reliable power supply and manufacturers’ products without interruptions.

Key Operation Settings You Can Control

Remote operating settings for industrial generators help you manage power events and operating conditions. Moreover. Here are a few things a reliable monitoring system lets you control:

The automatic alert system effectively protects sensitive components under harsh conditions. You can set up thresholds for metrics such as low fuel, high temperature, or battery issues. Likewise, when the reading reaches or crosses that certain threshold, you get instant alerts.

- Automatic startups during grid failure.

- After power restoration, it automatically shuts down the generator.

- For refueling alerts, you can set a minimum fuel level.

- Helps you determine safe temperature and controlled pressure.

- You can easily adjust the load and the running schedule.

- No need for physical labor, and control starts or stops automatically.

Real-Time Alerts Keep You Informed

That’s how you can maintain smooth production while avoiding problems. All the alerts help you respond quickly and maintain a consistent power supply, enabling factories to achieve excellent uptime and enhance reliability.

Fuel Monitoring Enhances Efficiency

A good industrial generator’s tracking system provides fuel levels and consumption readings over time. You can avoid unexpected fuel runs and monitor the overall fuel consumption rate.

Fuel trend analysis helps you minimize operating costs while improving fuel efficiency. You can easily track fuel leaks, theft, or inefficiencies in fuel handling with the proper monitoring settings. Also, the generator’s remote operating system helps you plan refills and reduce fuel waste.

Remote Operation Settings Save Time

With perfect operating systems for industrial generators, you can set ideal start/stop switches. Select automatic or manual modes and update operational settings remotely.

During emergencies such as a power failure, the automatic remote-operating setting starts the generator instantly. Meanwhile, when power returns, the entire industrial generator automatically shuts down.

Analytics and Reporting for Maintenance Planning

You not only analyze real-time data and generator performance with remote systems but also generate reports. Plan maintenance and receive automated performance reports daily, weekly, or monthly.

You can track patterns and trends in fuel consumption using these reports. Identify when generator components experience high stress and track when they require quick service. By monitoring the latest generator analytics, you can replace components at the right time. Also, it helps you avoid the risk of a bigger system failure at crucial times.

How Remote Monitoring Improves Safety

Remote monitoring and operating settings help ensure safety by reducing risk and providing real-time alerts. Also, a reliable tracking system in industrial generators:

- Avoids frequent site visits in hazardous conditions

- Track overheating, low oil pressure, and different electrical issues early.

- Provides instant warning or alerts for quick response.

- Offers reliable operation settings in critical locations like hospitals, data centers, and manufacturing factories.

Integration With Automated Transfer Switches (ATS)

When you install ATS in industrial generators, you streamline operations and minimize manual interventions. You can use an ATS to ensure a smooth transition between grid power and generator power. It sets up the automatic response to power events. Tracks every minor detail and shuts down automatically in case of an emergency.

Automated Control And Smart Genset Protection

You can manage fuel transfer with modern genset monitoring systems. Tracks fuel movement from storage to the main tank automatically and stops when the maximum level is reached. That’s how it makes sure your generators keep running when there is no grid power.

In critical conditions or emergencies, the system automatically shuts down. You also receive automated alerts for low oil pressure or high coolant temperature. That’s how you can protect your expensive equipment from severe damage and failure.

Cost Savings Through Remote Management

No need to spend on manual inspections, travel, or emergency service calls with smart generator operating systems. Track issues easily and prevent costly repairs and downtime.

It allows better fuel management and extends the maintenance schedule by improving the lifespan of the engine’s components.

How to Select the Right Monitoring System for Industrial Generators

Here are some essential features of a reliable remote monitoring system in industries:

- For precise ratings and measures, choose the right sensors.

- Instant updates for real-time responses.

- User-friendly interface for generator operators.

- Analytical reporting with data export options.

- Easy to install in the current infrastructure and systems.

- Both mobile and desktop are responsive for practical actions.

- Custom alerts and security selection.

- It should be compatible with multiple generators simultaneously.

Final Thoughts

Ultimately, it’s essential in modern factories to implement remote operating capabilities to ensure effective operations. You can manage fuel, fix leaks, reduce labor costs, and mitigate significant risks with innovative generator tracking systems. Streamline your factory production with proper safety. Buy reliable smart diesel or gas generators from Huaquan Power.

FAQs

What data does a remote monitoring system collect?

Remote systems can collect data on fuel, engine temperature, oil pressure, AC output, voltage, and frequency.

Does remote monitoring reduce maintenance costs?

Yes, smart, reliable remote monitoring settings for an industrial generator can reduce maintenance costs.