Power Plant Generators China Manufacturer

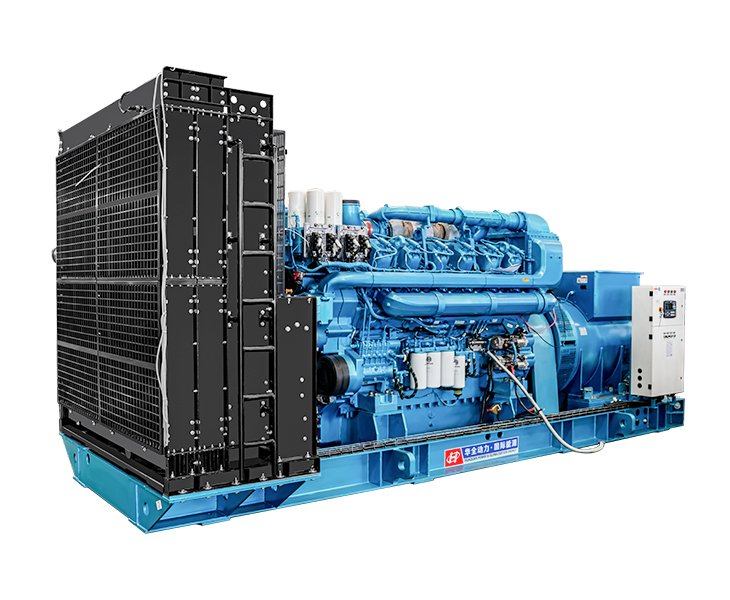

HUAQUAN power plant generator has the advantages of high conversion efficiency and stable output voltage. It is the core equipment for converting mechanical energy into electrical energy.

Our power plant generators can be used in thermal power plants. Among them, coal-fired power plants are our primary customer group. And hydropower plants, nuclear power plants are the same.

HUAQUAN power plant generators are commonly used in thermal power (coal-fired power plants), hydropower, nuclear power plants, etc. When installing and laying out power plant generators, the cost for factory expansion or renovation is relatively low. The existing power plant’s supporting power grid and other facilities are mature, and during expansion or renovation, the original system architecture can be directly adopted without the need to redesign the entire power generation process.

Power Plant Generators Model Selection

When selecting the power plant generators’ power range, various factors as fuel characteristics, grid structure, and investment return rate must be taken into consideration comprehensively.

This power plant generator is designed for small and medium-sized coal-fired power generation facilities and is suitable for regional power supply in developing countries. It is particularly suitable for scenarios such as coal mining areas and industrial parks.

This power plant generator is one of the main power generation sets in the current power system. It combines both scale benefits and operational flexibility, and is suitable for supporting regional power grids and providing comprehensive energy services for industrial parks.

This power plant generator is the main set of the modern power system, featuring both scale and advanced technology. It is particularly suitable as a regional base-load power source.

This power plant generator serves as the core power source for supporting the base load of large-scale power grids and acts as the stabilizing element of the power system.

Customized Services for Power Plant Generators

HUAQUAN can provide targeted solutions based on the specific needs of power plants, such as fuel characteristics, grid requirements, and environmental conditions.

Provide customization based on power plant types, such as thermal power, hydropower, nuclear power, etc.

Customized services available according to specific requirements, such as high-altitude type, cold-weather regions, coastal areas, etc.

In addition, our products come with intelligent monitoring modules, automatic start-stop protection modules, shock absorption configurations, and silent configurations etc. All of them have undergone strict quality inspections before leaving the factory to ensure high quality.

Core Advantages for Power Plant Generators

High power generation stability: It can continuously and stably output electricity, especially during peak electricity consumption periods, and it can quickly increase the power generation capacity to ensure the stability of the power grid.

Technologically mature and reliable: After long-term development, the technical system has been perfected, there is rich experience in equipment maintenance, and the construction and operation risks are relatively low.

Flexible site selection: The site can be chosen based on fuel supply and electricity demand. Being located close to the load center can reduce transmission losses.

Adapt to base load demand: Capable of bearing the basic load of the power system, able to meet the daily stable power supply requirements, and form complementarity with other types of power plants.

Fuel cost: The price of coal fluctuates greatly, which has a significant impact on the power generation cost of power plant generators.

Equipment maintenance cost: The daily maintenance of power plant generators, including equipment insurance, consumables expenses, and replacement parts costs, directly affect the power generation cost.

Pollution control cost: The emission control of pollution such as waste gas and wastewater has led to an increase in the environmental protection coasts for power plant generators.

It is necessary to clearly define the maintenance items and prepare the necessary plants for maintenance materials and spare parts.

It is necessary to reasonably arrange the maintenance schedule and draw a site layout management chart for generator maintenance to ensure that the maintenance work proceeds in an orderly manner.

It is necessary to compile or revise the generator maintenance document package, formulate the quality supervision plan, and inspect the maintenance tools.

Due to the long-term operation of power plant generators, the seals age, are damaged, or the components’ joints loosen due to vibration, resulting in a decline in sealing performance and prone to water leakage. Leaking can be detected through the airtight test method. By filling with nitrogen or compressed air, the leakage points can be identified, and the damaged components should be replaced in time.

Due to poor water quality in the internal cooling system, accumulation of oxides causing blockages, or the foreign objects during motor installation and major overhauls, blockage are prone to occur. This can be effectively prevented by strictly controlling the assembly and maintenance processes of the alternator and implementing corresponding inspection procedures.