China Mining Generator Manufacturer

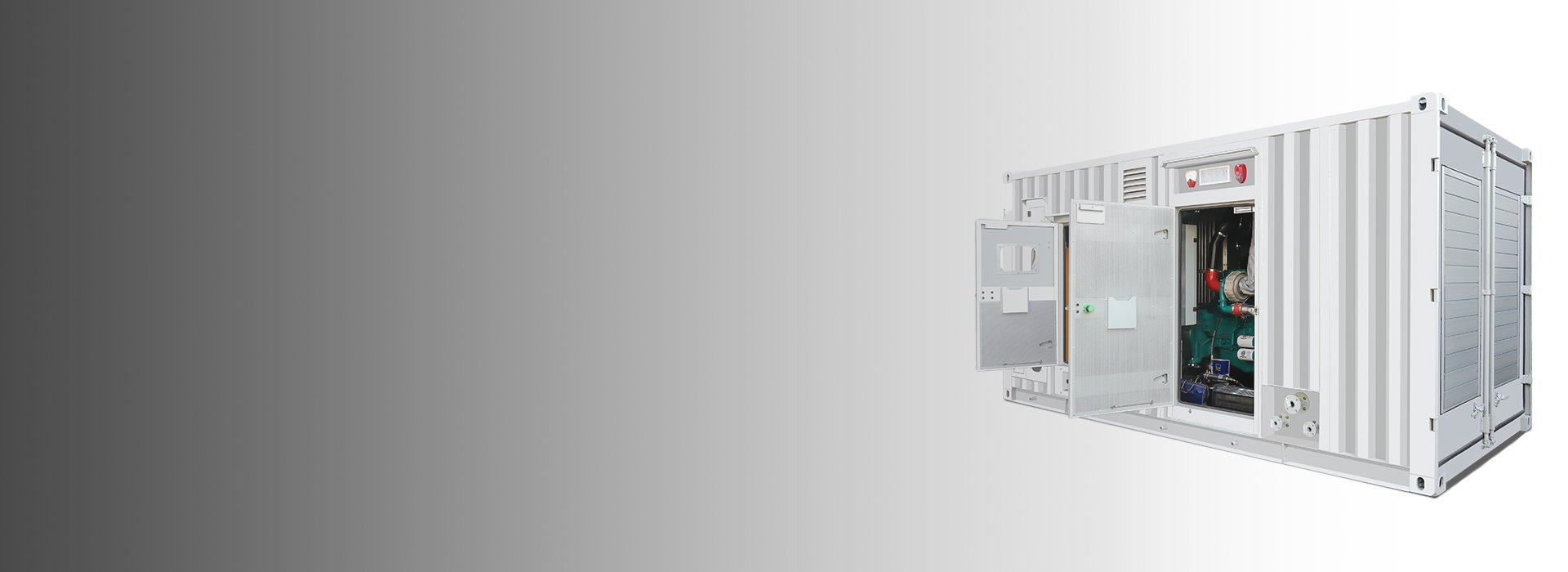

The mining generator has a wide range of applications and is the core power supply equipment for a mine. It can provide electricity for heavy equipment such as underground coal cutters, rock drilling vehicles, and tunneling machines.

Our mining generator is designed with explosion-proof features, which can eliminate the risk of gas and dust explosions caused by electric sparks. It is made of corrosion-resistant materials and can adapt to harsh working conditions. It can be remotely and intelligently monitored, providing early warnings for faults and solving the problem of equipment maintenance difficulties. It can be paired with a mobile trailer, eliminating the need for fixed infrastructure and enabling rapid deployment, thus addressing the challenge of frequent mining site relocation.

HUAQUAN mining generator is commonly used in open-pit mining, coal mining, gold mining, and other quarrying mines. The mine generator is not only a source of power but also the lifeline for ensuring safe production.

Mining Generator Selection

The power selection of a mining generator should be based on the application scenario and equipment load, accurately matching the power demand to avoid the risk of “overpowered solutions” or insufficient power supply.

It can meet the power demand of 80% of small and medium-sized mines, balancing economic efficiency and practically. It is suitable for powering underground mining equipment and auxiliary operations in open-pit mines, among other scenarios.

This power type product is the main power source for medium-sized mining areas, balancing both performance and cost-effectiveness, suitable for high-load continuous operation scenarios.

This power type product is a crucial pillar and key equipment in the mining energy system, driving the transition from medium to large-scale mining operations. It is suitable for harsh conditions involving high loads and continuous production.

It is the core power equipment for large-scale mines and intensive production scenarios, suitable for high-energy-consuming, continuous and intelligent mining operations.

Core Features of Mining Generator

Dust and explosion proof: IP54 and above, ATEX or MSHA certification required for explosive atmospheres.

Corrosion resistance: galvanized steel or fully encapsulated anti-corrosion coating (e.g., offshore mining scenarios).

Anti-vibration design: dynamic vibration-damping base to adapt to blasting vibration and rugged terrain.

Fuel and energy efficiency optimization: heavy oil compatibility, some models can burn heavy oil compatibility, some models can burn heavy oil (with preheating system); dual fuel option, diesel + natural gas hybrid, reducing fuel transportation costs in remote mining areas.

Performance Indicators for Mining Generators

Start-up time ≤ 15 seconds (with pre-lubrication system)

Power range: usually 500 kVA ~ 3 MW, large equipment in open pit mines (electric shovels, crushers) need to be connected in parallel.

Sudden load capacity: instantly withstand 150% load impact (such as ball mill startup).

Daily: check oil level/coolant, clean filter element surface dust

Weekly: test emergency stop function, check cable insulation

Every 500 hours: oil change (30% shorter intervals for mining conditions)

Annual overhaul: calibrated crankshaft concentricity, clean turbocharger

Problem:

Air filter element is clogged in 2-3 days, insufficient air intake leads to power reduction, and dust accumulation in radiator triggers high temperature alarm (>95℃).

Solution:

Adopt three-stage filtration system, i.e. cyclone separator → oil bath pre-filter → nano-fiber cartridge (the replacement cycle is extended to 200 hours), and add an automatic reversing fan (blowing dust in reverse for 30 seconds for every 1 hour of operation).

Common Problems:

Mud splashing clogs the heat sink (40% reduction in thermal conductivity), hard water scaling leads to corrosion and perforation of the cylinder liner.

Optimization Solution:

Add removable dust mesh in front of the radiator (cleaned by high pressure air gun every day), use deionized water + antifreeze mixed coolant (50% ratio of dithranol).

Case:

Ball mill startup caused voltage dips (instantaneous drop to 340V)

Solution:

Add magnetic saturation reactor (response time <10ms), and connect super capacitor bank in parallel (provide 2 seconds transient power compensation).