China Data Center Generator Manufacturer

With the core advantages of continuous power supply, fast response, high load capacity, and low failure rate, Huaquan data center generator is one of the key equipment to guarantee the power supply of the data center.

Switch to the data center generator within 10 to 30 seconds after the power grid failure to ensure a continuous power supply for the UPS, which can guarantee the continuous operation of the data Center during the power grid outage.

High transient response capacity, supporting 100% load step, preventing server downtime.

Silent container design (≤75dB), in line with urban environmental protection requirements, to avoid noise disturbance to residents.

A8 cloud platform, remote monitoring, reduces the need for manual inspections and alleviates the problem of excessively high costs for manual maintenance.

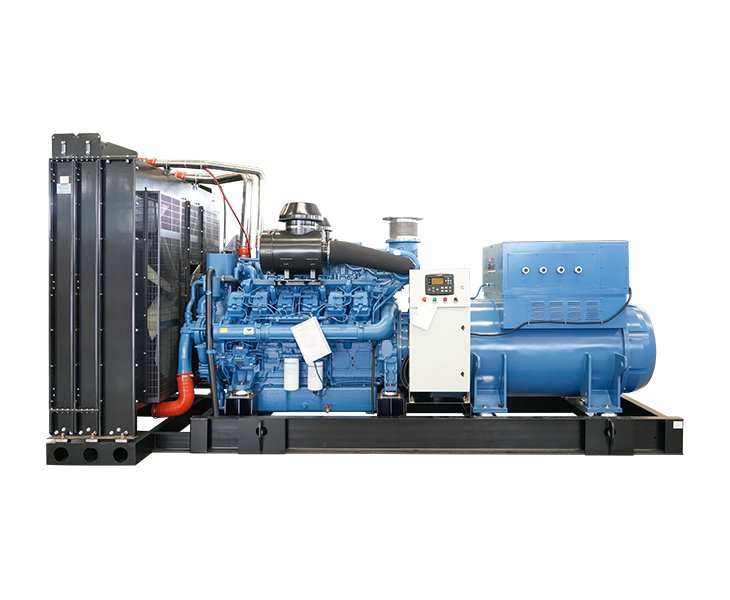

Data Center Generator

For the backup power supply of the data center, it is recommended to calculate the total load design with a redundancy factor of 1.2 to 1.3 times.

For a 2×800 kW diesel data center generator set connected in parallel (total 1600 kW), the recommended total design load is 1440 – 1560 kW.

For a 2×1000 kW diesel data center generator set connected in parallel (total 2000 kW), the recommended total design load is 1800 -1950 kW.

Recommeded total design load: 2250-2340 kW. Typically, 3×900 or 2×1400 kW diesel data center generators are connected in parallel.

Recommended total design load: 2800-3000 kW. Typically, 3×1000 kW or 4×800 kW diesel center generators are connected in parallel.

Application Scenarios of Data Center Generator

The data center generator is the last line of defense in the data center’s uninterrupted power supply system and is an indispensable core infrastructure. Data center generator is applied in: Backup power supplies for the Internet and cloud computing industries.

Application scenarios: Backup power for hyperscale data centers, securing backup power for cloud servers.

Backup power supply for ultra-large-scale data centers and backup power for cloud servers.

Backup power supply for the uninterrupted operation of core trading systems, and backup power supply for high-frequency trading scenarios.

Backup power supply for core servers, power protection for edge computing nodes, and backup power supply for submarine fiber optic cable landing stations.

Public security/fire command system, power protection, and epidemic data platform.

Medical imaging data center backup power supply, vaccine R&D supercomputing center backup power supply, and stem cell backup power supply.

Backup power supply for industrial Internet of Things (IoT) data middleware, backup power supply for intelligent manufacturing production line control center.

Backup power supply for AI training center, metaverse infrastructure, and blockchain nodes.

Backup power supplies for polar data centers, onboard data centers, and space data centers.

Main Types of Data Center Generators

Diesel generators as data center generators: easy to store fuel, wide range of power (tens of kW to several MW), suitable for long-time operation, are the most common and are equipped with the most units.

Gas generators as data center generators: environmentally friendly, lower emissions, but dependent on pipeline gas supply and may be limited in times of disaster.

Design Parameters for Data Center Generators

Power capacity: need to cover the full load demand of the data center, and reserve space for future extra expansion (usually configured according to N+1 or 2N redundancy).

Start-up time: from power failure to full load operation is usually within 10-30 seconds, with UPS (Uninterruptible Power Supply) to realize instant switchover.

Fuel reserve: at least 12-72 hours of operation (longer for demanding scenarios).

Weekly, check oil level/coolant, check standard: level between MIN-MAX.

Monthly, check no-load start test, check standard: continuously run for 5 minutes without alarms;

Semi-annually, change oil/filter, change standard: API CJ-4 grade oil;

Annually, full load test check, voltage fluctuation <±2% at 100% load.

Failure to start: Priority check 24 V battery pack (data centers commonly used 2×12 V in series)

Abnormal output voltage: focus on testing AVR and excitation winding insulation (resistance value > 1 MΩ)

Phenomenon: Fuel solidifies below -10°C and clog filters

Solution: Use winter grade diesel fuel (e.g. -35#)

Add a fuel heating kit (e.g. Webasto heater).

Causes: Governor response delay, sudden load changes (e.g., multiple air conditioning compressors starting at the same time) and AVR (Automatic Voltage Regulator) failure.